About Lunt Optics

Precision Is Our Legacy. Innovation Is Our Standard.

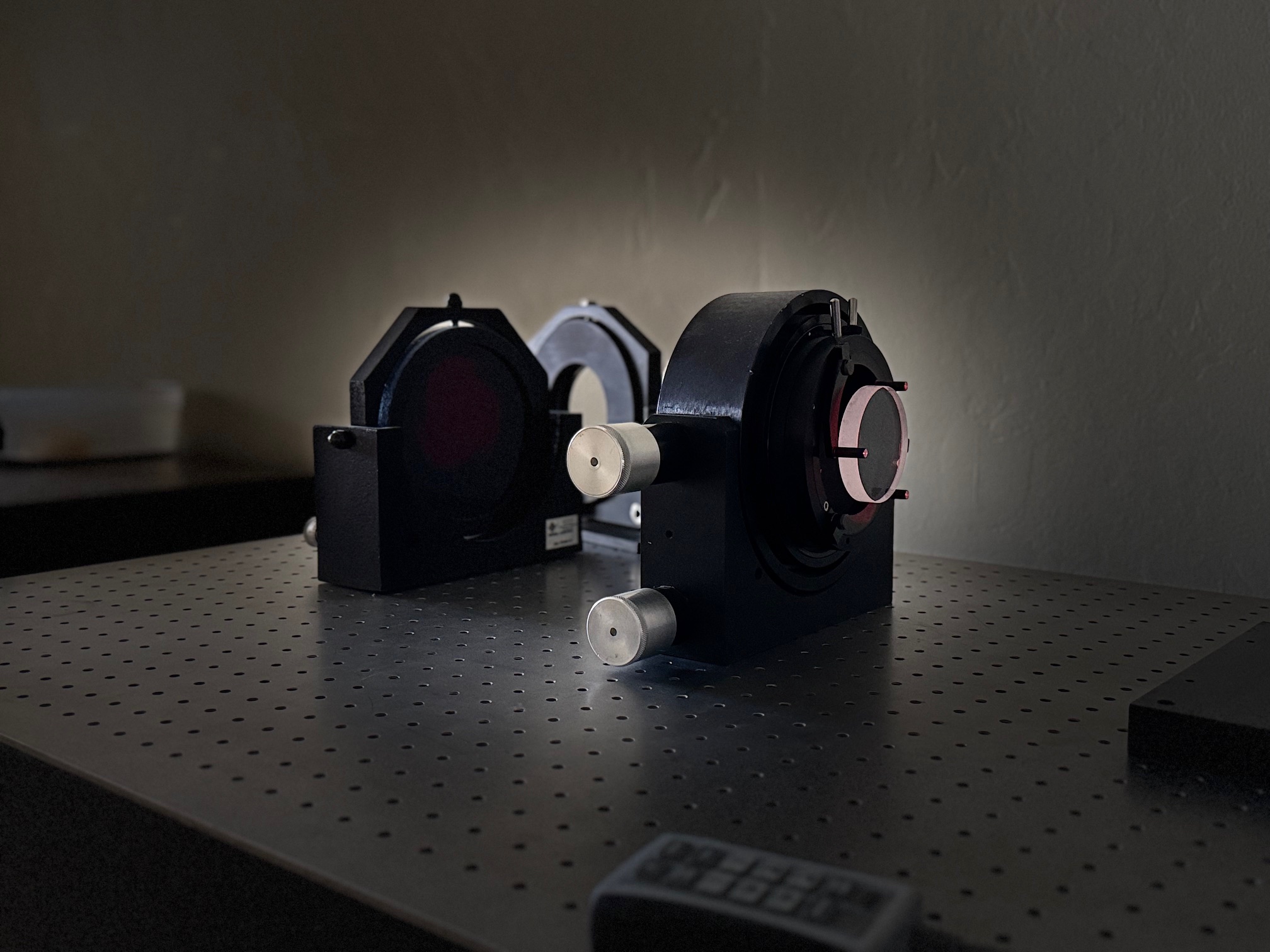

Lunt Optics is a U.S.-based manufacturer specializing in high-finesse Fabry–Pérot etalons, precision optical flats, and custom-coated mirrors built for performance-critical optical systems. From aerospace applications to national research laboratories, our optics serve as the foundation for technologies where tolerance, stability, and repeatability cannot be compromised.

We are engineers, fabricators, and problem-solvers committed to redefining what’s possible in optical precision. Every optic we produce reflects a legacy of excellence—and a future of innovation.

Manufacturing at the Highest Precision

All of our optics are fabricated in Tucson, Arizona using proprietary techniques and purpose-built polishing systems developed in-house.

Unlike high-speed commercial methods that leave edge roll-off or inconsistent flatness, Lunt’s continuous pitch polishing yields ultra-flat surfaces—across virtually the full aperture.

Why Technical Teams Choose Lunt

Defense Contractors

Designing laser systems and ISR platforms

Government Labs

Working on satellite optics and calibration standards

University Research Teams

Exploring spectroscopy, quantum optics, and laser stabilization

Photonics OEMs

Building instruments that require ultra-stable, high-quality filters and flats

Precision, Made Personal

Our team includes optical designers, coating engineers, and quality technicians who work closely with each customer.

Whether you're requesting a custom optical flat, tuning a Fabry–Pérot etalon to a target wavelength, or prototyping a novel optical instrument, we’re here to help you solve problems and build something exceptional.

Let's Build What's Next

Our Impact

Serving Industry, Defense, Government & Research

Lunt Optics proudly serves a diverse range of sectors that demand uncompromising optical performance. Our precision components enable and improve critical technologies in each of these areas.

Industry

Manufacturers of lasers, imaging systems, and metrology equipment rely on our ultra-flat mirrors and etalons for calibration and high-performance operation. The exceptionally low surface error and roughness of our optics (on the order of fractions of a wavelength) ensure minimal signal distortion in spectrometers and semiconductor inspection tools. By providing “better-than λ/30” reference flats and high-finesse interferometric etalons, we help industrial clients achieve tighter tolerances and greater efficiency in their products and processes. Explore products.

Defense & Aerospace

When it comes to mission-critical optical systems in aerospace and defense, there is no margin for error – and Lunt Optics delivers accordingly. Our fabrication protocols meet or exceed military specifications for optical components. For example, the solar optics Andy Lunt developed have passed stringent Mil-Spec tests for safety and reliability. We bring that same rigor to Lunt Optics’ offerings, supplying optical flats and etalon assemblies for applications such as airborne imaging platforms, LIDAR and rangefinding systems, and satellite-borne spectrometers. Andy Lunt’s background in aerospace optical fabrication gives us insight into the needs of defense contractors and space agencies. We understand how to build optics that withstand harsh environments (thermal fluctuations, vibration, etc.) while maintaining diffraction-limited performance. From holographic sights to atmospheric sensors, Lunt Optics components are engineered to perform reliably in the field, ensuring defense and aerospace clients can trust our optics in the most demanding scenarios. Explore products.

Government Agencies

Lunt’s reputation for excellence has led to collaborations with U.S. government entities like the US Department of Energy, NASA and the U.S. Air Force. Through Lunt Solar Systems, our team has a proven track record of delivering specialized optics for deep space and solar observation missions and research projects. Lunt Optics continues this tradition, providing government labs and observatories with custom etalon filters, large-aperture flats, and other optical elements for experimentation and instrumentation. Our optics have been used in everything from solar observatory upgrades to airborne science platforms. We are proud to be a Made-in-USA manufacturer, and we understand the procurement and documentation standards required by government customers. Whether it’s a contract for a national laboratory or a federal research program, Lunt Optics is equipped to meet strict compliance, quality, and delivery expectations. Explore products.

Scientific Research & Academia

Universities and research institutions around the world turn to Lunt Optics for research-grade optical components. The research sector often pushes the envelope of what optical systems can do – ultra-narrowband filters for studying the Sun, high-finesse cavities for physics experiments, or reference flats for precision interferometry. Lunt Optics is an ideal partner in these endeavors. Our etalons have exceptionally high finesse and throughput, enabling scientists to isolate spectral lines with sub-Ångström precision. Meanwhile, our large optical flats (available in custom sizes) serve as calibration standards in interferometric setups and adaptive optics testbeds. We’ve worked with educational institutions on providing optics for solar telescopes used in student observatories, and with national research facilities on one-off optics for prototyping new laser systems. In one independent benchmark, a Lunt-manufactured etalon outperformed several competitors in a blind test, exhibiting superior peak transmission and bandwidth stability– a testament to the level of quality we deliver for researchers who simply cannot compromise on performance. By collaborating closely with scientists and engineers, we ensure that our products not only meet theoretical specifications but also integrate smoothly into experimental setups, accelerating the pace of discovery. Explore products.

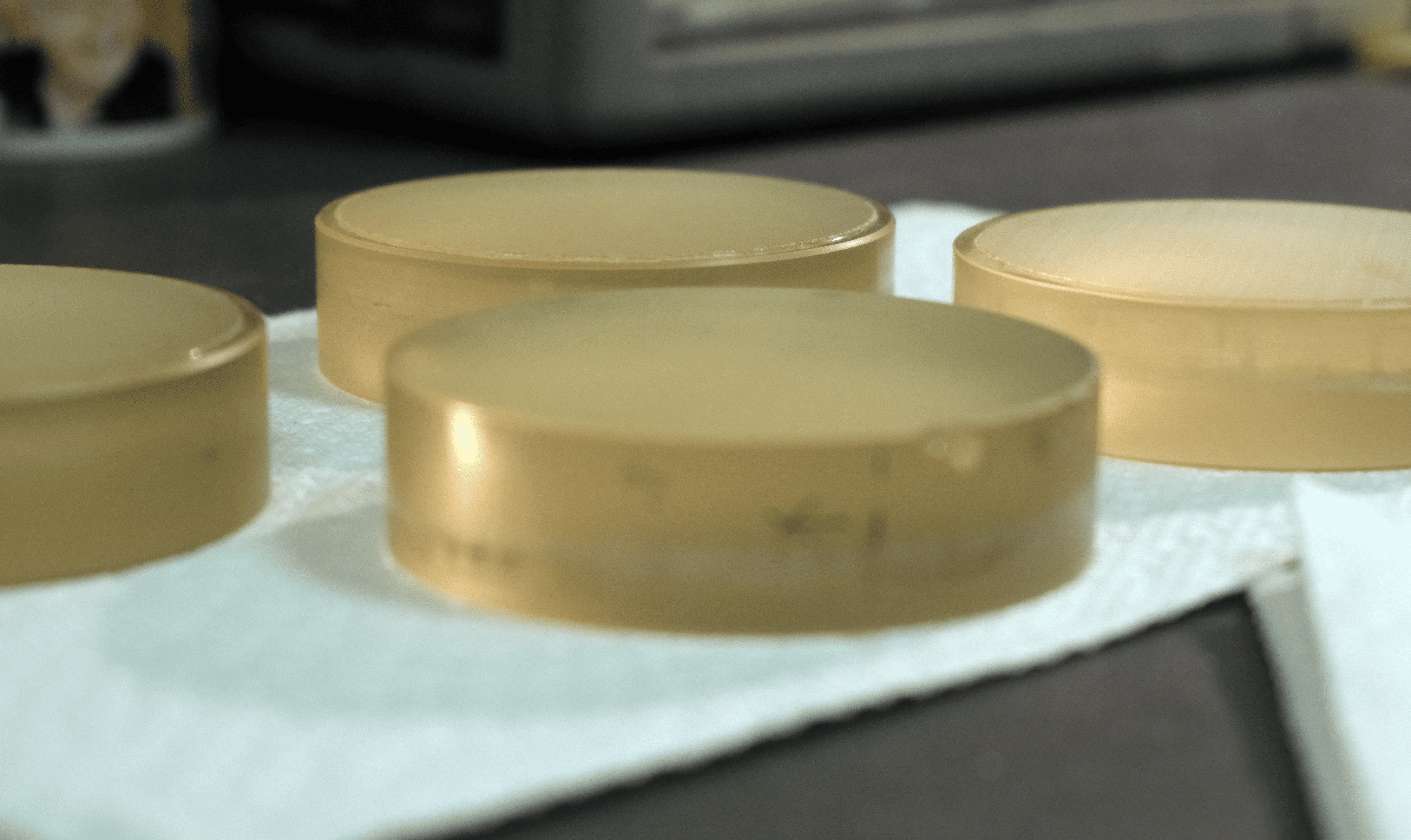

Commitment to Precision Manufacturing

Precision is the foundation of Lunt Optics. We pride ourselves on manufacturing optics to tolerances far beyond typical commercial standards. Our etalon plates and flats are polished using a proprietary continuous polishing process that prioritizes accuracy over speed. Unlike high-speed polishing methods that yield roughly 1/4-wave flatness with distorted edges, our slow, meticulous approach achieves surfaces flat to 1/50th wave or better across virtually the entire optic (98%). Each plate is polished on specialty pitch laps in a 24/7 process, taking days rather than hours – but the results speak for themselves. This unwavering dedication produces some of the world’s most precise flats; for example, we fabricated a 3″ low-expansion glass wafer (just 0.007″ thick) with a transmitted wavefront error better than 1/100th wave across its full aperture. (For context, achieving that level of flatness is extraordinary in the optics industry.) Independent testing at facilities like Brookhaven National Laboratory confirmed the performance of our optics at this extreme precision. To maintain such standards, we custom-build our polishing machines and even develop proprietary testing techniques beyond conventional interferometry, allowing us to detect errors that standard instruments cannot. Every optic is rigorously double-tested (plates are mated and tested against each other) to ensure parallelism and flatness meet our spec before it ever leaves our lab. The result of this careful process is an optical surface with incredibly low roughness and an exceptionally flat profile – in other words, laser-quality optics that form the heart of high-finesse etalon systems.

- 1

Meticulous Polishing

Our proprietary continuous polishing on custom-built machines achieves λ/40 flatness across 98% of the optic, taking days to ensure laser-quality surfaces.

- 2

Premium Substrates & Coatings

Using UV-grade fused silica and 0.1% low-reflectance coatings proven in solar telescopes, we ensure minimal defects and maximum durability.

- 3

Proprietary Testing

Every optic is double-tested with proprietary methods beyond standard interferometry, verifying parallelism and flatness to exceed specifications.

Innovation Driving Performance

Innovation is at the heart of Lunt Optics’ philosophy. We don’t accept the compromises that were once considered “standard” in optical fabrication – instead, we develop new techniques to overcome them. For instance, older etalon manufacturing methods often required adding a central spacer or using thinner plates to force surfaces into parallelism, compensating for less-precise polishing. In contrast, Lunt Optics perfected a process using thicker etalon plates (for rigidity) polished so precisely that no central spacer is needed. This yields an unobstructed aperture and more uniform performance. We also favor advanced air-pressure tuning for etalons (developed during Andy Lunt’s work with Lunt Solar Systems) instead of mechanical tilting or compression used by legacy designs. By uniformly adjusting air pressure in the etalon cavity, we achieve wavelength tuning that is more stable and evenly distributed, resulting in sharper, contrast-rich images without compromising the etalon’s alignment. Lunt Optics continually invests in R&D like this to refine our products – from novel spacer geometries (e.g. Andy’s patented “root3” spacer system for large etalons to improved thermal stability techniques – all aimed at delivering optics that perform at the cutting edge of what’s physically possible. Our team’s deep experience (spanning aerospace, astronomy, and precision manufacturing) fuels a culture of problem-solving and continuous improvement. We embrace new challenges from custom client requirements, often developing one-of-a-kind solutions that later inform our standard production processes. In short, innovation at Lunt Optics isn’t a buzzword; it’s the daily practice of combining optical science with creative engineering to push performance to new heights.

Spacer-Free Etalons

Our thicker, precisely polished plates eliminate central spacers, providing unobstructed apertures and uniform performance.

Air-Pressure Tuning

Advanced air-pressure tuning ensures stable, high-contrast wavelength control, outperforming legacy mechanical methods.

Patented Innovations

Novel designs like the “root3” spacer system enhance thermal stability, pushing the boundaries of optical performance.

Our Promise

Unwavering Quality and Customer Focus

No optic leaves our facility without thorough testing to certify it meets our published specifications – and often our internal standards are even more stringent. This dedication to quality is a hallmark carried over from Lunt Solar Systems, where no astronomical product requires a higher level of quality control than a solar instrument. As Andy Lunt has often stated, we are proud to put “Made in the USA” on our products and stand behind their performance. Explore products.

Our team’s hands-on approach means the company’s founder and engineers are directly involved in the design and testing of every batch. This personal investment in the outcome ensures that each customer, whether a hobbyist astrophotographer or a government lab, receives the very best we can produce. We also pride ourselves on supporting our clients: offering expert guidance during product selection, accommodating custom requests, and providing responsive after-sales support. Contact us.

Get in Touch

Contact Us

Contact us via email or phone for personalized assistance with your optical requirements. Contact us.

Based in Tucson, Arizona, we’re proud to be a Made-in-USA manufacturer. Learn more.